Class 12 Chemistry Notes on Batteries, Cells and Corrosion

Batteries, Cells and Corrosion

Batteries

These are source of electrical energy which may have one or more cells connected in series.

For a good quality battery it should be reasonably light. compact and its voltage should not vary appreciably during its use.

Primary Batteries

In the primary batteries, the reaction occurs only once and after use over a period of time battery becomes dead and cannot be reused again.

(i) Dry cell or Leclanehe cell

Anode-Zinc container

Cathode-Graphite rod surrounded by MnO2 powder

Electrolyte-Paste of NH4Cl + ZnCl2

Cathode reaction,

2MnO2(s) + 2 NH+4(aq) + 2e– → Mn2O3(s) + 2NH3(g) + H2O(l)

Anode reaction,

Zn(s) → Zn2+(aq) + 2e –Cell potential 1.25 V to 1.5 V

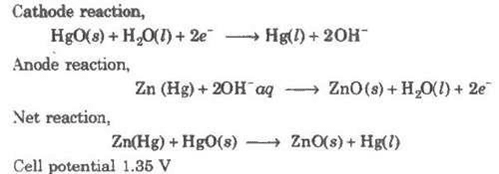

(ii) Mercury cell

Anode-Zn-Hg amalgam

Cathode-Paste of (HgO + C)

Electrolyte-Moist paste of KOH-ZnO

Secondary Batteries

These cells can be recharged and can be used again and again, e.g.,

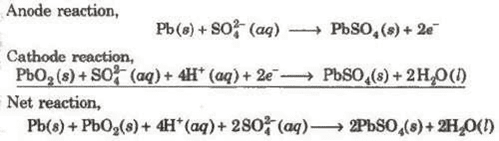

(i) Lead Storage battery

Anode-Spongy lead

Cathode-Grid of lead packed with PbO2

Electrolyte-38% H2SO4 by mass

When recharged the cell reactions are reversed.

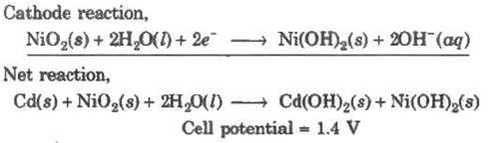

(ii) Nickel-cadmium storage cell

Anode-Cadmium

Cathode-Metal grid containing NiO2

Electrolyte-KOH solution

Anode reaction,

Cd(s) + 2OH–(aq) → Cd(OH)2(s) + 2e–

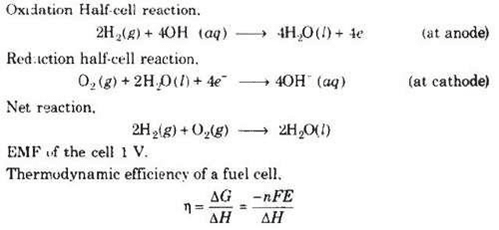

Fuel Cells

Galvanic cells which use energy of combustion of fuels like H2, CH4, CH3OH, etc., as the source to produce electrical energy are called fuel cells. The fuel cells are pollution free and have high efficiency.

Hydrogen-Oxygen Fuel Cell

Electrodes-Made of porous graphite impregnated with catalyst (Pt, Ag or a metal oxide).

Electrolyte-Aqueous solution of KOH or NaOH

Oxygen and hydrogen are continuously fed into the cell.

Corrosion

Slow formation of undesirable compounds such as oxides, sulphides or carbonates at the surface of metals by reaction with moisture and other atmospheric gases is known as corrosion.

Factors Affecting Corrosion

- Reactivity of metals

- Presence of moisture and atmospheric gases like CO2, SO2, etc.

- Presence of impurities

- Strains in the metal

- Presence of electrolyte

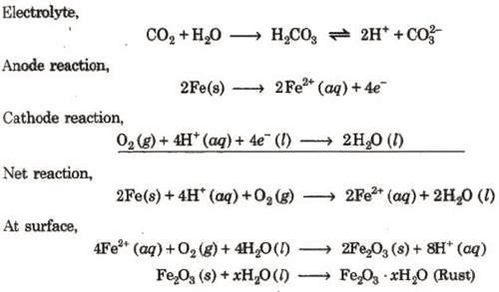

Rusting of Iron-Electrochemical Theory

An electrochemical cell, also known as corrosion cell, is developed at the surface of iron.

Anode- Pure iron

Cathode-Impure surface

Rusting of iron can be prevented by the following methods :

- Barrier protection through coating of paints or electroplating.

- Through galvanisation or coating of surface with tin metal.

- By the use of antirust solutions (bis phenol).

- By cathodic protection in which a metal is protected from corrosion by connecting it to another metal that is more easily oxidised.